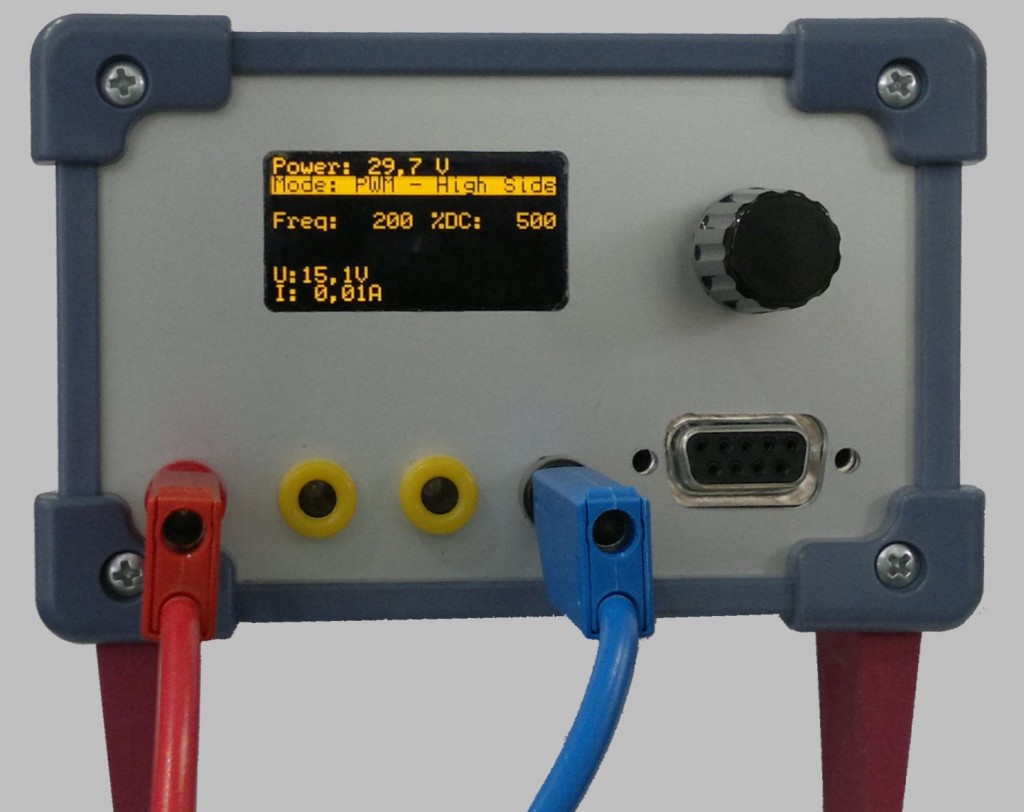

In order to conduct these tests adequately suitable in our house developed testing and commissioning equipment for automotive components perfectly. By intuitive interface, the HPPS is perfect test for manually. Also finding the right operating parameters for electro-hydraulic components, thanks to the HPPS no longer a problem.

Configuration parameters such as voltages, currents, frequencies or PWMs can be determined in no time.

read more ...

While working with or on ECU–controlled automotive systems almost always lack a diagnostic device even smaller error tests can be done determines the electrical operating parameters, controls or. Next the unit developed in-house is designed excellently for troubleshooting. The Intuitive operation facilitates thereby the handling of this unit immensely. In addition to manual operation is still a remote control function to disposal, this remote control function (CAN) also allows autmatisch running tests.

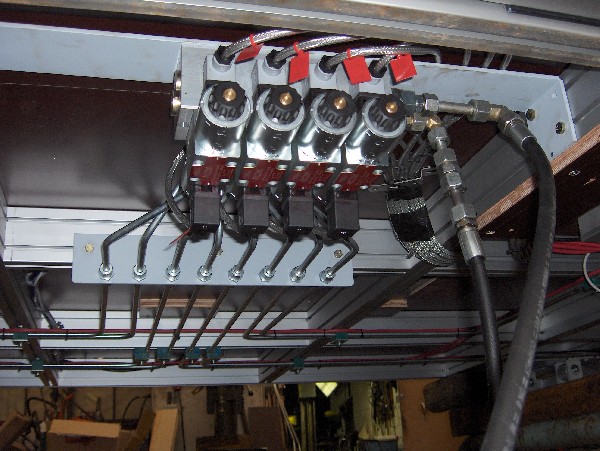

- Solenoid tests at various operating frequencies

- method of hydraulic axes (2-way – Dual Function)

- Determination of currents

- Determination of duty cycles

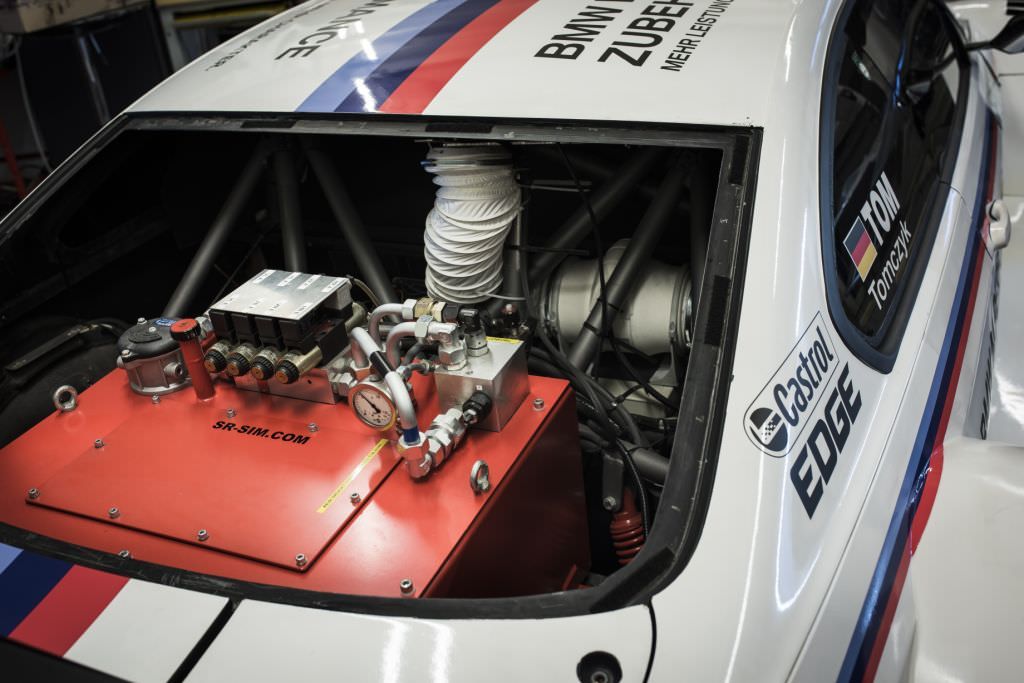

- Incremental encoder simulation

- automatically running tests using the remote control function

- ease of transportation

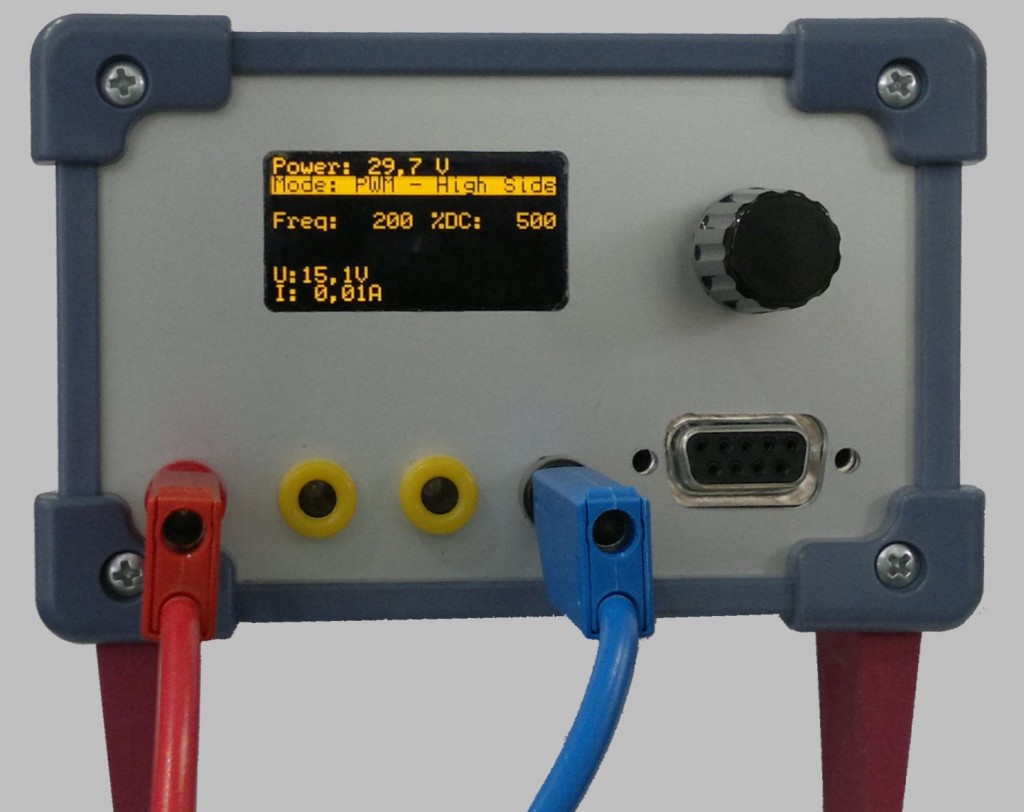

- Output voltage / current output

- Large work area (6V–36V ???)

- Troubleshooting

- Check the wiring

- intuitive operation

- Operating parameters determine / control