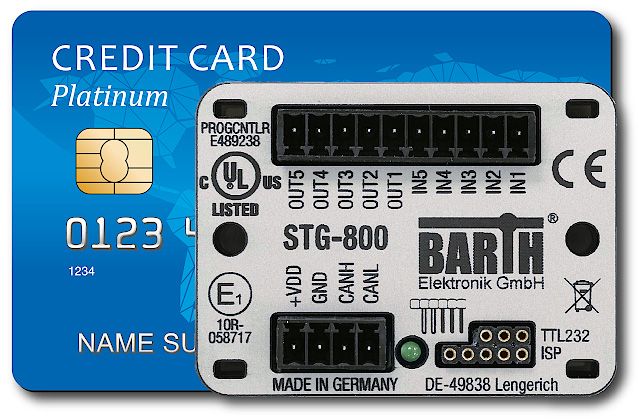

BARTH® Elektronik GmbH specializes in the development and manufacturing of ultra-compact, powerful, and cost-efficient miniPLCs (Programmable Logic Controllers). The product portfolio includes various models (e.g., STG series) as well as accessories such as expansion modules, programming cables, and development software.

Key Features of BARTH Products

- Miniaturization: Extremely small form factor, ideal for applications with limited space.

- Performance: Despite their small size, the PLCs offer sufficient computing power for complex control tasks.

- Energy Efficiency: Low power consumption, predestined for battery-operated or energy-conscious systems.

- Robustness: Designed for industrial environments, often featuring a wide temperature range and high EMC immunity.

- Easy Programming: Programming is typically done using intuitive software tools (e.g., miCon-L), often with graphical programming languages (e.g., Instruction List or Function Block Diagram), which simplifies entry and shortens development time.

- Comprehensive Interfaces: Depending on the model, they offer digital/analog inputs and outputs, PWM, I2C, SPI, RS232, CAN bus, and other communication options.

Advantages of BARTH miniPLCs

Barth Elektronik products can be used to implement a wide variety of applications in industry, research, automation, and even the hobby sector. The main advantage lies in the combination of compact design, flexibility, and performance, making them ideal for embedded control tasks and cost-sensitive projects.

Possible Applications include:

- Small Machine Controls: For individual machines, packaging machines, filling systems, or feeding systems where a fully-fledged “large” PLC would be oversized.

- Prototyping and Small Series: Fast realization and validation of control logics for new machine concepts.

- Retrofitting: Modernization of existing, older machines with flexible and modern control technology.

- Decentralized Control Units: In complex systems for controlling subsystems or individual modules (e.g., in your Vertical Farming application or in test benches).

- Data Logging: Recording of process data for optimization and documentation.

- Control of smaller building functions such as lighting, heating, ventilation, or blinds.

- Intelligent room or facility monitoring.

- Control of auxiliary aggregates, lighting systems, monitoring of battery management systems, or specific functions in special vehicles.

- Manufacturers of devices or subsystems can integrate the miniPLC directly into their products to provide intelligent, adaptable control logic without having to develop their own electronics.

Conclusion: Barth Elektronik enables developers and companies to implement intelligent controls for a wide range of applications with minimal effort and maximum flexibility, especially where space, cost, and energy efficiency are crucial factors. They bridge the gap between simple microcontrollers and complex, expensive industrial PLCs.

Example Projects

- Sensor-guided gas generator with STG-850 variant

- Interface between CAN-Plain and CANopen for KEB inverters

- Distance measurement with ultrasonic sensor and STG-800

- BLDC motor control with STG-850

- Stepper motor control with STG-850

- Oven control with STG-855

- Pattern recognition with STG-800

- Robot positioning and dosing system with UR5, STG-800, and DMA-20

- Map-controlled gas generator with STG-850 variant

- Pump control with STG-800

- Temperature monitoring with STG-850 variant

- Sound output with the STG-820

- Stroboscope trigger based on STG-800

- Temperature logger

- Networked lighting control

- Fan control based on STG-810

- Control for a goods dispensing machine

- Control of a swivel device for a plasma cleaner